We perform

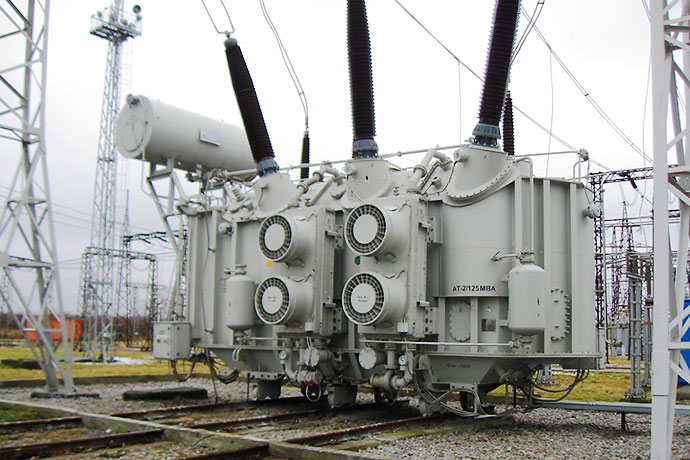

Repair of transformers

The repair program is developed on the basis of the executed design developments and the analysis of a design of the repaired equipment, data of tests and diagnostic conclusions, data of base of emergency, databases on repairs and tests.

Documented experience in repair and reconstruction of transformers and shunt reactors

- Selection, adaptation, reconstruction, restoration, testing of oil-filled inlets, on-load tap-changers, cooling systems, respiratory systems

- Development and implementation of a set of works to restore the characteristics of transformer oil

- Organization and implementation of repair work on our own and (or) with the involvement of specialized organizations

- Supply of spare parts, materials and special technological equipment for repair work

Technical guidance and execution of repair work by specialists of SEC "ZTZ-Service"

- Work on 110-750 kV transformers directly on the installation site with special insulation protection

- Works with replacement of windings, in the conditions of poorly equipped substations

- Work to extend the service life of transformers and shunt reactors

- Drying in the field of highly moist insulation

- Removal of products of aging with special regenerative oils

The repair department, was the first in the former USSR, who began to use methods of drying and washing insulation active part, by spraying transformer oil with special additives (Reginol). Due to that it is possible to significantly improve the dielectric properties of the insulation.

On the basis of modernization projects developed by the design department of SEC "ZTZ-Service", specialists of the repair department are able to develop repair documentation and perform turnkey repairs of any complexity.

SEC "ZTZ-Service" performs modernization of power transformers and shunt reactors:

- Replacement of transformer oil protection from nitrogen to film, with production of the new expander according to our project if necessary

- Processing of the expander and bringing its volume to the optimum. (To avoid seasonal drain, add transformer oil to the equipment)

- Complex modernization of shunt reactors of РОДЦ 110000/750. We are the undisputed leaders in this work and our experience is used by all repair companies that encounter similar works

- Replacement of inputs of the old design with new ones

- Replacement of transformer protection against overpressure from the exhaust pipe with safety valves

- Optimization of hot oil intake points by cooling system

- Installation of fire extinguishing system by SERGI, France.

We use cookies to provide necessary website functionality, improve your experience and analyze our traffic. By using our website, you agree to our cookies usage.